Discover our complete range of plain bearings and joint components reliable, durable, and easy to install. Engineered to optimize the performance and service life of your industrial equipment. Our solutions self-lubricating, metallic, polymer, or bimetallic cover all applications, from standard uses to the most demanding operating conditions.

Our plain bearings and joint components stand for precision, durability, and maximum operational reliability in industrial applications. Whether for standard solutions or complex operating conditions, we provide precisely engineered components that enhance efficiency and reduce downtime. Benefit from innovative materials, advanced manufacturing processes, and uncompromising quality.

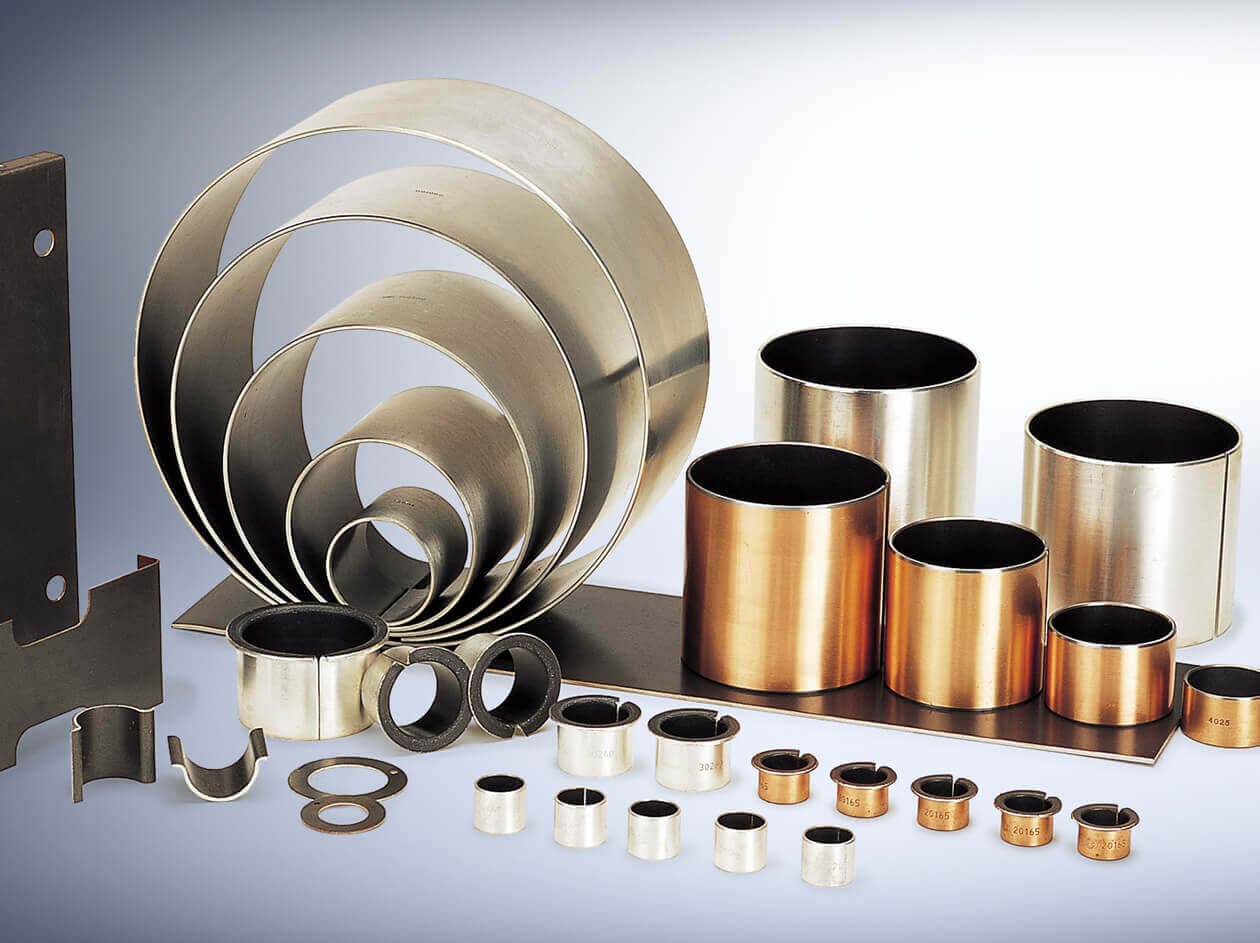

Self-lubricating plain bearing made from a steel–bronze–polymer composite, maintenance-free and ready to install. Manufactured in accordance with DIN ISO 3547 and RoHS compliant, featuring a PTFE sliding layer for minimal friction and extended service life.

Wrapped, low-maintenance dry plain bearings made from a steel–bronze–polymer composite. Manufactured in accordance with DIN ISO 3547, suitable for oil and grease lubrication, ready to install, and RoHS compliant.

Wrapped, low-maintenance and maintenance-free plain bearings made from solid bronze. Manufactured in accordance with DIN ISO 3547, suitable for oil and grease lubrication, ready to install, and RoHS compliant.

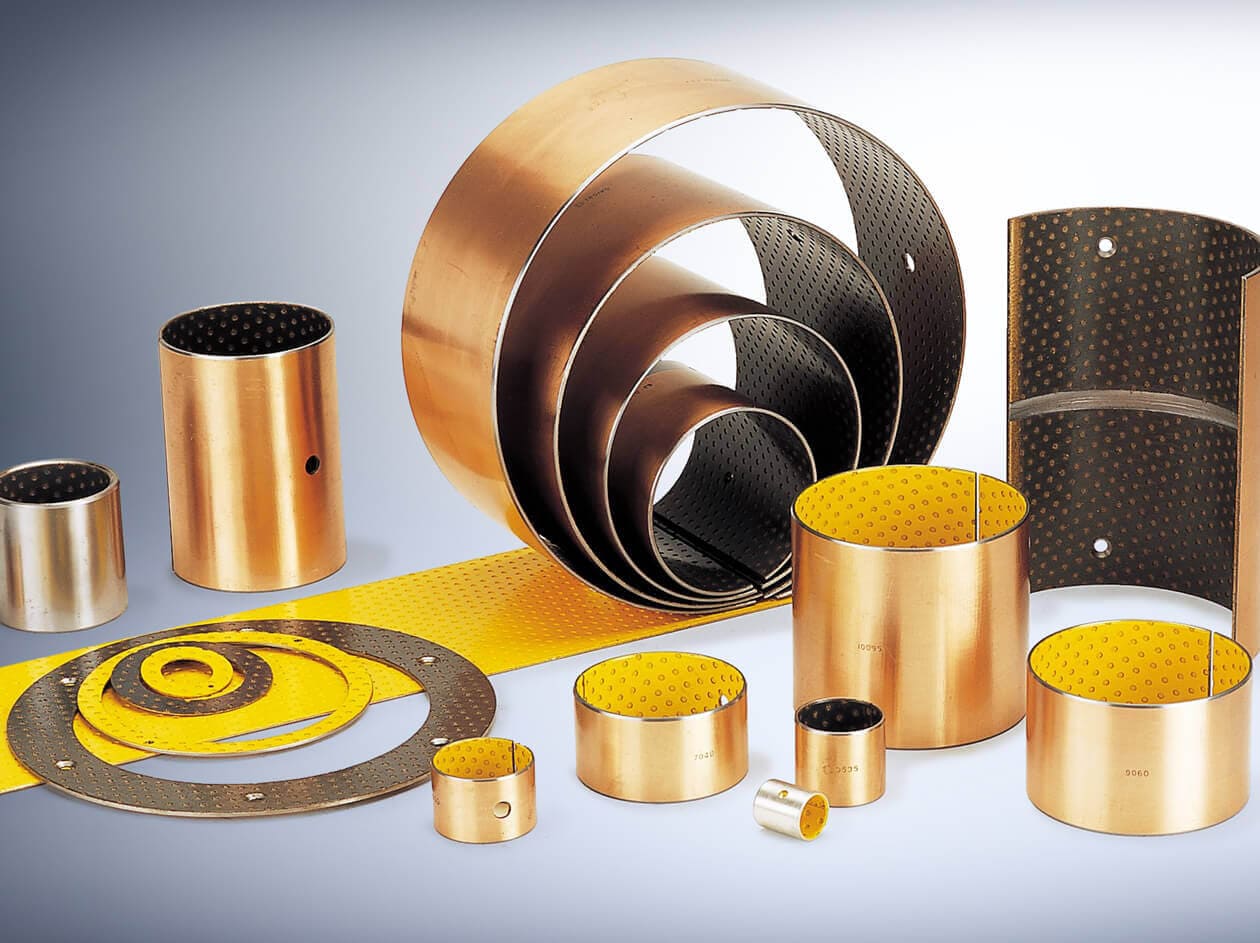

Maintenance-free sliding elements made from solid bronze with integrated solid lubricant inserts. Wear-resistant, durable, and corrosion-resistant. Also available in RoHS-compliant versions upon request.

Machined solid plain bearings, manufactured in accordance with DIN ISO 4379 or to customer drawings. Suitable for oil and grease lubrication and ready to install. Highly wear-resistant, durable, and reliable ideal for demanding industrial applications.

Filament-wound composite plain bearings. Wear- and impact-resistant, chemically resistant, ready to install, and RoHS compliant ideal for demanding industrial applications.

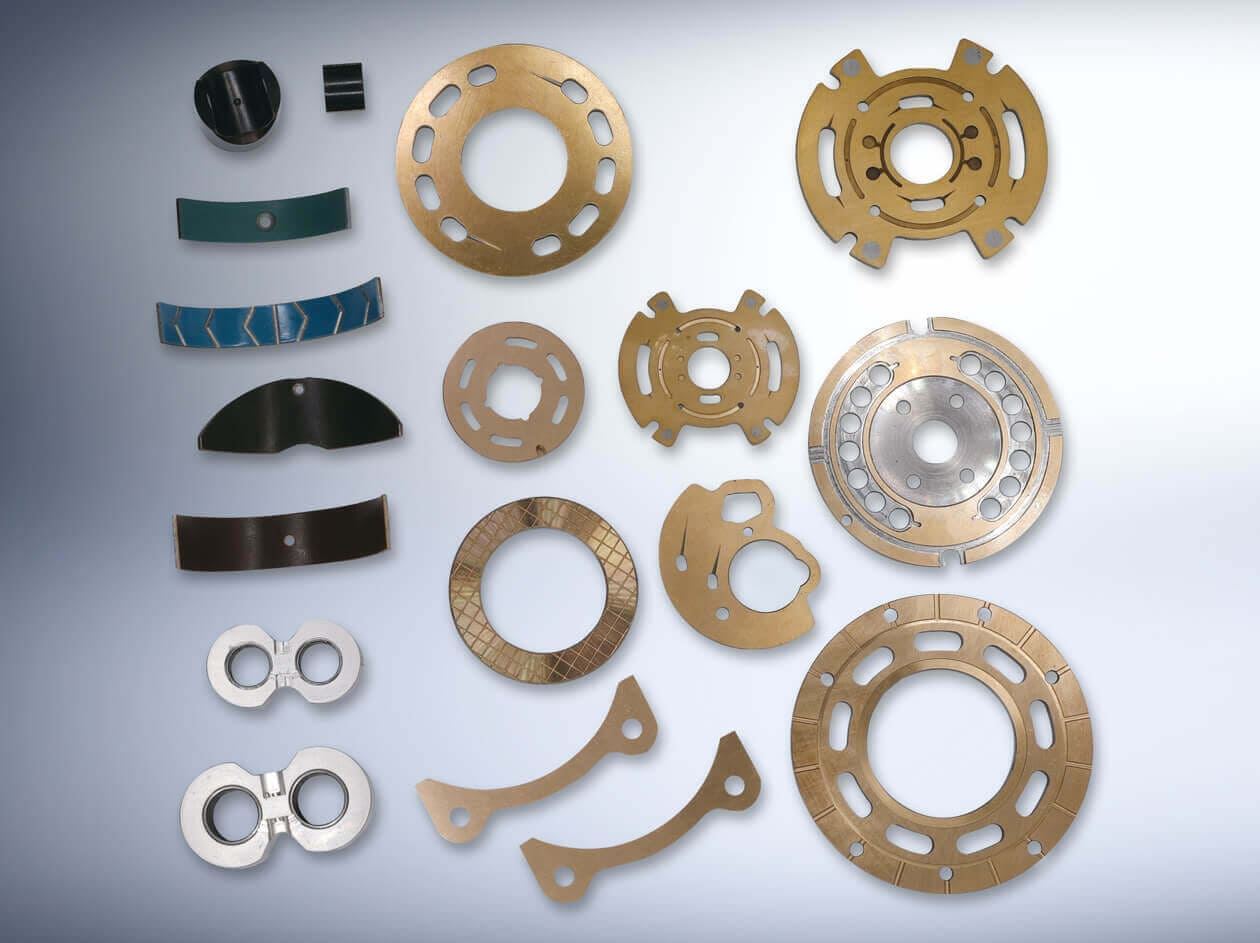

Spherical plain bearings and rod ends for oscillating, pivoting, or rotating movements at low speeds, compliant with DIN ISO 12240. They offer flexibility and precision and are ideal for industrial joint mechanisms.

Multi-layer plain bearings for lubricated applications, featuring a low coefficient of friction and high wear resistance. Deliver maximum performance and extended service life, even in demanding industrial environments.

Filament-wound composite plain bearings. Wear- and impact-resistant, with excellent chemical resistance, ready to install, and RoHS compliant. Ideal for demanding industrial applications.

Maintenance-free plain bearings made from bronze mesh, offering high load capacity and excellent wear resistance. Ideal for applications with demanding requirements for stability, precision, and service life.

Porous, self-lubricating plain bearings, maintenance-free ideal for hard-to-reach or maintenance-intensive applications. Ensure continuous and reliable lubrication, even under heavy use.

Thrust washers and high-performance components for particularly demanding applications, including bronze, bimetal, and resin-coated variants. Engineered for maximum durability and performance, even under the toughest conditions.

In-depth knowledge of plain bearings, manufacturing, and applications in the automotive, hydraulics, material handling, and other industries.

We are a reliable partner, offering solid expertise and proven competence in the field of plain bearings.

We listen closely to our customers to develop technically suitable and cost-efficient solutions.

Supported by technical service and CSB Bearings Technologies in research, development, and material industrialisation, to efficiently meet our customers’ requirements.

All products are developed according to international environmental standards and comply with the RoHS directive, which restricts the use of hazardous substances.